“Yesterday, I went to a hotel with my mistress, and at the entrance, I see my father-in-law’s car parked.

I lost all desire and, of course, if he saw me, I would have problems.

I explained to my mistress that today was impossible, and she left upset.

Out of frustration, I broke both mirrors and went home. The next day, I went to see him and laugh at the fact that his car had no mirrors. He was very upset, and I asked him:

What’s wrong with you? You seem upset.

How the hell wouldn’t I be? Yesterday, I lent your wife the car, and she brought it back without mirrors.”

Next joke

Dad, I want to get married!

First, apologize!

But why?

Just apologize!

What for? What did I do?

You need to apologize!

But why???

Apologize, I said!

Please, just give me a reason!!!

First, apologize.

Okay, dad… I’m sorry!

Perfect, now you’re ready! Your training is over. When you learn to apologize for no reason, then you can get married!

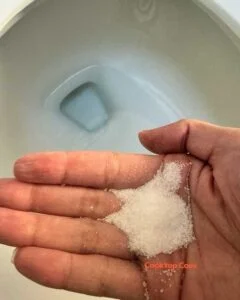

Unveiling the Toilet’s Hidden Ally: Unleashing the Potential of Table Salt

### Unveiling the Toilet’s Hidden Ally: The Power of Table Salt

Are you tired of toilet clogs and bad odors? Don’t worry! We’ve found a surprising solution that your plumber might not tell you about. Common table salt can be your bathroom’s new best friend. This simple kitchen item can help keep your toilet clean and working well while also being cheap and good for the environment. In this article, we’ll show you how salt can help your toilet and why plumbers might keep this tip to themselves.

### The Sneaky Helper: Salt

**Tackling Clogs:** Salt can help break down things that block toilets, like too much toilet paper and waste. By using salt regularly, you can prevent future clogs and keep your toilet working properly.

**Banishing Bad Odors:** Want to get rid of bad smells? Salt is a natural way to absorb odors. It can soak up moisture in areas where bacteria grow and neutralize stinky smells, making your bathroom more pleasant.

**Removing Mineral Stains:** Stubborn stains from minerals can be tough to clean, but salt can help. When you use salt as a scrub, it can dissolve these deposits, making your toilet shine.

**Economical and Environmentally Friendly:** Using salt means you can skip expensive chemical cleaners. This budget-friendly and eco-friendly choice helps protect our water systems from harmful chemicals.

Leave a Reply